MC Series Automatic Multi-Station Thermoforming Machine

Form Cut Stack Machine

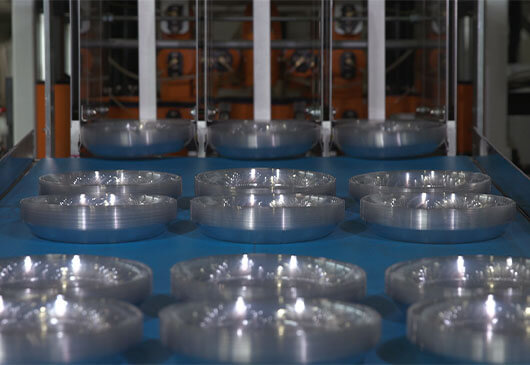

Application of form-cut-stack thermoforming machine for thin wall food and industrial packaging.

- Forming Method: Vacuum Forming / Pressure Forming

- Maximum Sheet Width: 320 ~ 820 mm (details see specification)

- Maximum Dry Cycle Speed: 60 cycle/min (details see specification)

Features

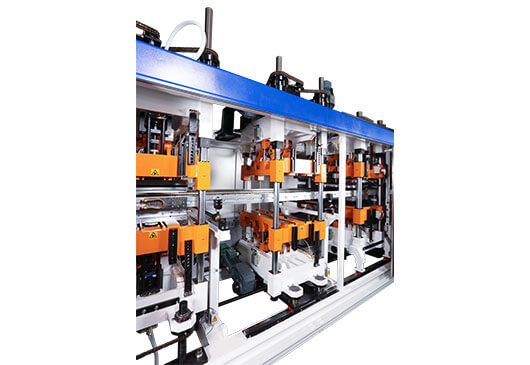

Sunwell Global’s MC Series multi-station thermoforming machine is engineered for maximum efficiency in thin-wall packaging production. This automatic thermoforming machine utilizes advanced steel rule die cutting technology combined with a chain index system, heating oven, and positive and negative pressure forming to deliver high-quality results. The compact design integrates automatic counting, stacking, product cutting, and scrap rewinding, optimizing productivity.

- Output: Achieves up to 60 cycles per minute, processing materials like PP, PS, OPS, PE, PVC, APET, CPET, and PLA.

- Energy-Efficient Automation: Precision temperature control, full servo system, and robust toggle drive mechanism ensure reliable, consistent production.

- Quick Mold Exchange: Simple and cost-effective mold changes minimize downtime, making the machine suitable for both small and medium-scale production runs.

Applications

Lids

Food Containers

Fruit Punnets

Plates / Dishes

Styrofoam Food Packaging

Poultry & Meat Trays

Specifications

| MODEL | MCS800 | MCS1000 |

|---|---|---|

|

Configuration

|

Form-Cut-Stack Multi-Station; steel rule die technology

|

Form-Cut-Stack Multi-Station; steel rule die technology

|

|

Application

|

Thin wall food and industrial packaging

|

Thin wall food and industrial packaging

|

|

Stations No.

|

3 or 4

|

3 or 4

|

|

Max. Cycle Speed

|

60 cycles / Min.

|

50 cycles / Min.

|

|

Sheet Index

|

AC Servo driven chain index feed

|

AC Servo driven chain index feed

|

|

Heat Tunnel Length (mm)

|

1,800

|

2,400

|

|

Heating Elements

|

Ceramic

|

Ceramic

|

|

Forming method

|

Positive and negative pressure forming

|

Positive and negative pressure forming

|

|

Forming direction

|

Either above or below sheet forming

|

Either above or below sheet forming

|

|

Maximum Sheet With (mm)

|

860

|

1060

|

|

Forming Mold Size (mm)

|

Max. 570(L) x 820(W)

Min. 250 (L) x 290(W) |

Max. 750(L) x 1000(W)

Min. 450 (L) x 500(W) |

|

Max. Depth of Draw (mm)

|

130

|

130

|

|

Shut-height (mm)

|

Top: 250~350

Bottom: 200~250 |

Top: 250~350

Bottom: 200~250 |

|

Platen Travel (mm)

|

Top: 150

Bottom: 150 |

Top: 150

Bottom: 150 |

|

Forming Platen Driven

|

AC Servo; toggle mechanism actuation

|

AC Servo; toggle mechanism actuation

|

|

Forming Tonnage (tons)

|

30

|

50

|

|

Pre-Punch Mold Size (mm)

|

Max. 570(L) x 820(W)

Min. 250(L) x 290(W) |

Max. 750(L) x1000(W)

Min. 400(L) x 290(W) |

|

Shut-height (mm)

|

Top: 250~350

Bottom: 250 |

Top: 250~350

Bottom: 250 |

|

Platen Travel (mm)

|

Top: 150

Bottom: 150 |

Top: 150

Bottom: 150 |

|

Pre-punch Driven

|

AC Servo; toggle mechanism actuation

|

AC Servo; toggle mechanism actuation

|

|

Pre-punch Tonnage (tons)

|

30

|

30

|

|

Cutting Size (mm)

|

550(L) x 800(W)

|

730(L) x 980(W)

|

|

Shut-height (mm)

|

Top: 85~185

Bottom: 180 |

Top: 85~185

Bottom: 180 |

|

Platen Travel (mm)

|

Top = 150

|

Top = 150

|

|

Cutting Tonnage (tons)

|

60

|

90

|

|

Stacking Size (mm)

|

550(L) x 800(W)

|

730(L) x 980(W)

|

|

Stacking Method

|

Up or Down stacking by servo; Robotic is option

|

Up or Down stacking by servo; Robotic is option

|

|

Control System

|

B&R or YASKAWA

|

B&R or YASKAWA

|

|

Floor Space (M)

|

12.5(L) x 3.3(W) x 3.3(H)

|

14(L) x 3.6(W) x 3.3(H)

|

|

Machine Weight (kg)

|

12,000

|

16,000

|