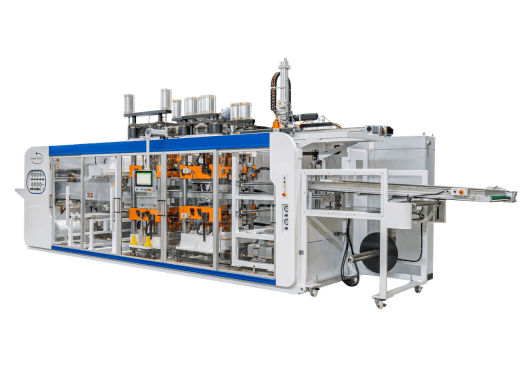

MC Series Automatic Multi-Station Thermoforming Machine

Form–Cut–Stack Solutions for Thin-Wall Packaging Production

Designed for form–cut–stack thermoforming applications in thin-wall food and industrial packaging.

- Forming Method: Vacuum Forming / Pressure Forming

- Maximum Sheet Width: 320 ~ 820 mm (details see specification)

- Maximum Dry Cycle Speed: 60 cycle/min (details see specification)

Features

Sunwell Global’s MC Series is an automatic multi-station thermoforming system engineered for high-speed, thin-wall packaging production. By combining steel rule die cutting technology with a chain index system, heating oven, and both positive and negative pressure forming, the machine delivers stable forming quality and accurate cutting performance.

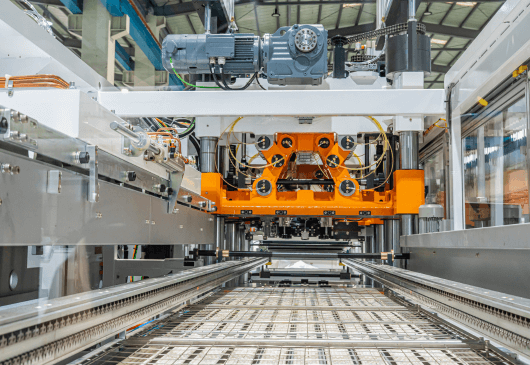

Integrated Form–Cut–Stack Automation

The compact system integrates automatic product cutting, counting, stacking,

and scrap rewinding into a single production line. This integrated design

reduces labor requirements, optimizes floor space, and improves overall

production efficiency.

High-Speed Output for Thin-Wall

Applications

The MC Series achieves production speeds of up to 60 cycles per minute,

supporting a wide range of thermoplastic materials, including PP, PS, OPS,

PE, PVC, APET, CPET, and PLA, making it suitable for diverse packaging

applications.

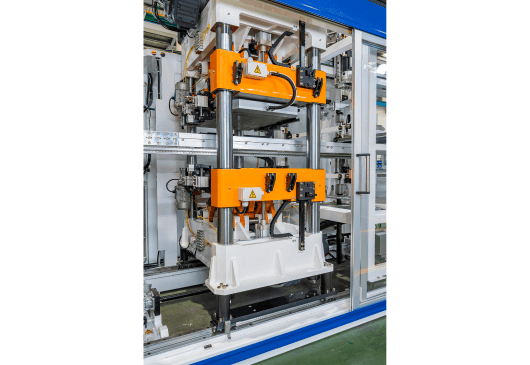

Energy-Efficient and Stable Operation

Precision temperature control, a full servo-driven system, and a robust toggle

drive mechanism ensure consistent forming performance, high repeatability, and

energy-efficient operation during continuous production.

Designed for production flexibility, the MC Series features a simple and fast mold exchange system that minimizes downtime. This makes it well-suited for small to medium batch production as well as frequent product changes.

Applications

Lids

Food Containers

Fruit Punnets

Plates / Dishes

Styrofoam Food Packaging

Poultry & Meat Trays

Specifications

| MODEL | MCS800 | MCS1000 |

|---|---|---|

|

Configuration

|

Form-Cut-Stack Multi-Station; steel rule die technology

|

Form-Cut-Stack Multi-Station; steel rule die technology

|

|

Application

|

Thin wall food and industrial packaging

|

Thin wall food and industrial packaging

|

|

Stations No.

|

3 or 4

|

3 or 4

|

|

Max. Cycle Speed

|

60 cycles / Min.

|

50 cycles / Min.

|

|

Sheet Index

|

AC Servo driven chain index feed

|

AC Servo driven chain index feed

|

|

Heat Tunnel Length (mm)

|

1,800

|

2,400

|

|

Heating Elements

|

Ceramic

|

Ceramic

|

|

Forming method

|

Positive and negative pressure forming

|

Positive and negative pressure forming

|

|

Forming direction

|

Either above or below sheet forming

|

Either above or below sheet forming

|

|

Maximum Sheet With (mm)

|

860

|

1060

|

|

Forming Mold Size (mm)

|

Max. 570(L) x 820(W)

Min. 250 (L) x 290(W) |

Max. 750(L) x 1000(W)

Min. 450 (L) x 500(W) |

|

Max. Depth of Draw (mm)

|

130

|

130

|

|

Shut-height (mm)

|

Top: 250~350

Bottom: 200~250 |

Top: 250~350

Bottom: 200~250 |

|

Platen Travel (mm)

|

Top: 150

Bottom: 150 |

Top: 150

Bottom: 150 |

|

Forming Platen Driven

|

AC Servo; toggle mechanism actuation

|

AC Servo; toggle mechanism actuation

|

|

Forming Tonnage (tons)

|

30

|

50

|

|

Pre-Punch Mold Size (mm)

|

Max. 570(L) x 820(W)

Min. 250(L) x 290(W) |

Max. 750(L) x1000(W)

Min. 400(L) x 290(W) |

|

Shut-height (mm)

|

Top: 250~350

Bottom: 250 |

Top: 250~350

Bottom: 250 |

|

Platen Travel (mm)

|

Top: 150

Bottom: 150 |

Top: 150

Bottom: 150 |

|

Pre-punch Driven

|

AC Servo; toggle mechanism actuation

|

AC Servo; toggle mechanism actuation

|

|

Pre-punch Tonnage (tons)

|

30

|

30

|

|

Cutting Size (mm)

|

550(L) x 800(W)

|

730(L) x 980(W)

|

|

Shut-height (mm)

|

Top: 85~185

Bottom: 180 |

Top: 85~185

Bottom: 180 |

|

Platen Travel (mm)

|

Top = 150

|

Top = 150

|

|

Cutting Tonnage (tons)

|

60

|

90

|

|

Stacking Size (mm)

|

550(L) x 800(W)

|

730(L) x 980(W)

|

|

Stacking Method

|

Up or Down stacking by servo; Robotic is option

|

Up or Down stacking by servo; Robotic is option

|

|

Control System

|

B&R or YASKAWA

|

B&R or YASKAWA

|

|

Floor Space (M)

|

12.5(L) x 3.3(W) x 3.3(H)

|

14(L) x 3.6(W) x 3.3(H)

|

|

Machine Weight (kg)

|

12,000

|

16,000

|