EPS, XPS, EPE Re-Pelletizing Machines

In-House Foam Waste Recycling & Reprocessing Solutions

- Material: EPS, XPS, EPE EPP

- Granular Size: 3-5 mm

- Output: 100-600 kg/hr (details see specification)

Features

Sunwell Global offers an advanced range of die-face cutting, water-flushed re-pelletizing lines, engineered for stable operation, high output, and consistent pellet quality. These systems enable manufacturers to reduce material waste, lower raw material costs, and support sustainable production.

Automated Scrap Feeding and Material Flow Control

Foam scrap and fluff are conveyed to the hopper via an air conveying system

with reverse jet fabric filtration. A rotating anti-bridging blade inside the

hopper ensures smooth material flow into the forced feeding system, delivering

a uniform and controlled feed to the extruder.

High-Capacity Extrusion with Low Energy

Consumption

The extruder features a large-diameter feed zone screw design, providing

sufficient surface area and residence time for gradual plasticizing and

complete melt homogenization. This design supports high throughput while

maintaining low power consumption.

Efficient Degassing and Melt

Purification

An integrated vacuum degassing system removes volatile contaminants and trapped

gases from the melt, preventing air bubbles and ensuring a stable, continuous

melt flow to the die. A continuous screen changer maintains consistent process

conditions during filter changes and improves final pellet cleanliness.

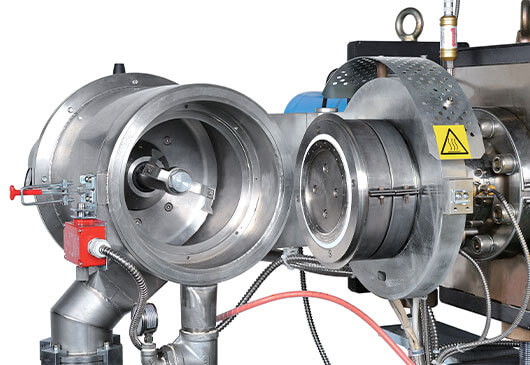

Precision Die-Face Cutting and Process

Synchronization

The horizontally mounted die-face cutter is synchronized with the extruder and

forced feeder speeds for stable and operator-friendly operation. An adjustable

dial gauge ring allows precise blade-to-die gap setting, optimizing cutting

quality and extending blade service life.

Water-Flushed Cooling and Pellet Drying

System

A side-hinged water ring pelletizing drum with tangential cooling water

injection rapidly cools and flushes pellets to a dehydrator or vibratory dryer,

followed by cyclone collection. The system produces uniform pellets (3–6 mm)

with low moisture content, ensuring excellent downstream processing

performance.

Applications

Specifications

| MODEL | DRC85 | DRC100 | DRC120 |

|---|---|---|---|

|

Material

|

EPS; XPS; EPE

|

EPS; XPS; EPE

|

EPS; XPS; EPE

|

|

Material feed

|

Side Force Feed

|

Side Force Feed

|

Side Force Feed

|

|

Screw Dia. (mm)

|

85

|

100

|

120

|

|

Extruder Type

|

Conical Single

|

Conical Single

|

Conical Single

|

|

Output (kg/h)

|

100 ~200

|

200 ~ 300

|

500 ~ 600

|

|

Granular size (mm)

|

3~5

|

3~5

|

3~5

|

|

Moisture

|

3% Less

|

3% Less

|

3% Less

|

|

Degassing

|

By Vacuum

|

By Vacuum

|

By Vacuum

|

|

L/D

|

34/1

|

34/1

|

34/1

|

|

Cutting type

|

Die Face Cut, Water Flush

|

Die Face Cut, Water Flush

|

Die Face Cut, Water Flush

|

|

Die type

|

Horizontal (Melt Flow Direction)

|

Horizontal (Melt Flow Direction)

|

Horizontal (Melt Flow Direction)

|

|

Drive System

|

SIEMENS AC Drive with FLENDER Gearbox

|

SIEMENS AC Drive with FLENDER Gearbox

|

SIEMENS AC Drive with FLENDER Gearbox

|

|

Space requirement

|

10(L) x 2.5(W) x 4(H)

|

11(L) x 2.5(W) x 5(H)

|

12(L) x 2.5(W) x 6(H)

|