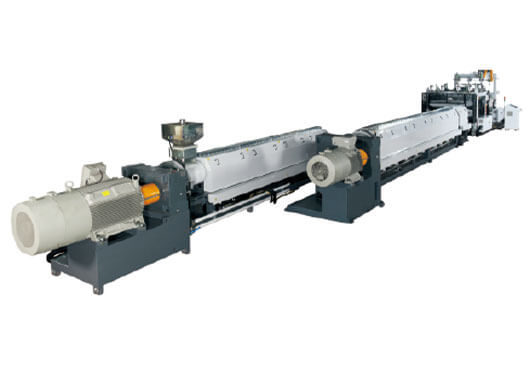

Foam Insulation Board Extrusion (XPS Extrusion) Lines

High-Performance XPS Foam Board Solutions for Building Insulation

- Material: GPPS

- Material Thickness: 20-200 mm (details see specification)

- Output: 300-1200 kg/hr (details see specification)

- Density: 26~45 kg/M3

Features

Sunwell Global is a leading manufacturer of XPS foam board extrusion lines, providing advanced and reliable solutions for high-quality insulation board production. Our tandem XPS extrusion systems are engineered for stable, continuous operation and utilize CO₂ as a blowing agent to support environmentally responsible and energy-efficient manufacturing.

High Production Capacity and Dimensional

Flexibility

Sunwell XPS extrusion lines offer output capacities from approximately 250 to

1,200 kg/hr, producing boards with thicknesses from 20 mm to 200 mm and widths

from 600 mm to 1,200 mm. This wide production range allows manufacturers to

meet diverse insulation market requirements.

Automated Raw Material Handling and

Blending

The system supports automatic handling and precise blending of up to eight raw

materials, including flame retardants and nucleating agents. This ensures a

homogeneous melt and consistent foam structure in the primary XPS extruder.

Precise Blowing Agent Metering and

Control

CO₂, plasticizers, and optional HFC blowing agents are accurately metered using

ATEX-compliant, triple-head diaphragm pumps with mass flow measurement,

ensuring stable foam density, uniform cell structure, and superior board

quality.

Advanced Tandem Extrusion Technology

The secondary XPS extruder is equipped with a high-mixing, low-shear screw, a

water-cooled bimetallic barrel, and motorized valve control to minimize

temperature fluctuations. A static mixer and homogenizing tube ensure melt

uniformity before entering the chrome-plated flat XPS die, which features

quick-opening capability, fine-adjustment bolts, and Teflon guide shoes for

precise board formation.

Efficient Calibration, Cooling, and

Cutting Systems

The board calibration unit uses temperature-controlled plates and a heavy-duty

haul-off system designed to withstand CO₂ expansion pressure. A fail-safe

pneumatic quick-opening mechanism enhances operational safety. Cooling

conveyors allow controlled board stabilization before edge milling and precise

length cutting by a high-speed double-blade cross cutter.

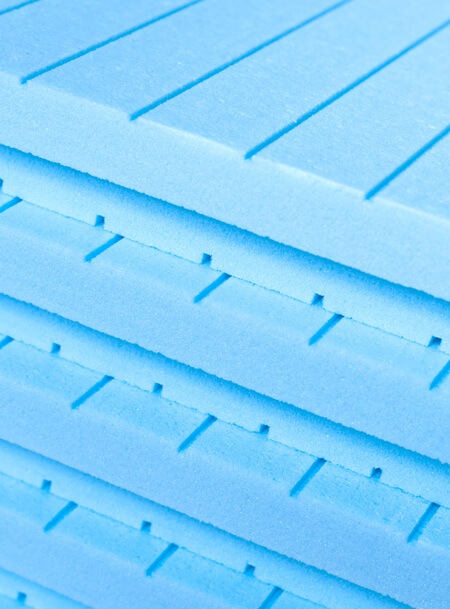

Flexible Surface Finishing and Edge

Profiling

Boards can be planed or grooved to meet specific insulation market

requirements. Edge profiles such as flat, tongue-and-groove, or shiplap can be

produced after additional cooling and milling.

Fully Automated Stacking and Packaging

Solutions

Sunwell provides fully automatic board stacking and six-sided wrapping systems,

with optional add-ons such as in-line product printing, soundproofing, and dust

extraction—delivering a complete, turnkey XPS insulation board production

solution.

Applications

Insulation

Specifications

| MODEL | FEX120150XPS | FEX150200XPS | FEX180250XPS |

|---|---|---|---|

|

Thickness (mm)

|

20~100

|

25~160

|

30~200

|

|

Width (mm)

|

600; 900; 1,200

|

600; 900; 1,200

|

600; 900; 1,200

|

|

Length (mm)

|

1,000~3,000

|

1,000~3,000

|

1,000~3,000

|

|

Throughput (kg/h)

|

300~500

|

500~800

|

800~1,200

|

|

Density (kg/M3)

|

26~45

|

26~45

|

26~45

|

|

Extruder Type

|

Tandem

|

Tandem

|

Tandem

|

|

Screw Dia. (mm)

|

120 and 150

|

150 and 200

|

180 and 250

|

|

L/D

|

34/1 and 32/1

|

34/1 and 32/1

|

34/1 and 32/1

|

|

Blowing agent

|

Hydrocarbon, CO2, DME, HCFC, HFC

|

Hydrocarbon, CO2, DME, HCFC, HFC

|

Hydrocarbon, CO2, DME, HCFC, HFC

|

|

Drive System

|

SIEMENS AC drive with FLENDER gearbox

|

SIEMENS AC drive with FLENDER gearbox

|

SIEMENS AC drive with FLENDER gearbox

|

|

Barrel material

|

Bimetallic

|

Bimetallic

|

Bimetallic

|

|

Cooling system

|

Air cool for primary

Proportional motorized water cool for secondary |

Air cool for primary

Proportional motorized water cool for secondary |

Air cool for primary

Proportional motorized water cool for secondary |

|

Edge Profile

|

Shiplap, Tongue and Groove

|

Shiplap, Tongue and Groove

|

Shiplap, Tongue and Groove

|

|

Surface formation

|

Groove, Plane, Emboss

|

Groove, Plane, Emboss

|

Groove, Plane, Emboss

|

|

Floor Space (M)

|

80L x 15W x 6H

|

100L x 15W x 8H

|

120L x 20W x 8H

|