Foam Tube / Profile Extrusion Lines

EPE Foam Solutions for Insulation and Protective Packaging

- Material: LDPE

- Dimension: See Specification

- Output: 10-40 kg/hr (details see specification)

- Density: 22-30 kg/M3

Features

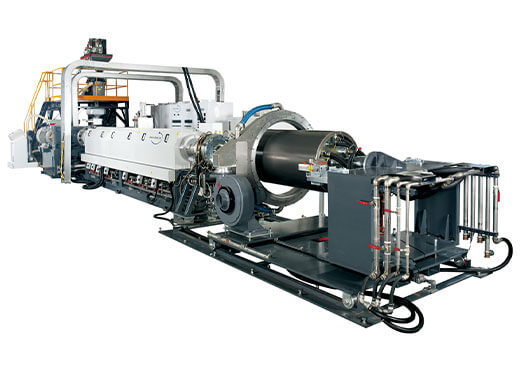

Sunwell Global is a leading supplier of EPE

foam tube and profile extrusion lines, delivering reliable and efficient

solutions for continuous foam product manufacturing. Our systems are engineered

for stable operation, long service life, and consistent foam quality, with

production capacities ranging from approximately 35 to 100 kg/hr.

Automated Material Handling and Precise Blending

LDPE raw materials, together with GMS (Glycerin Monostearate) and talc, are

automatically dosed and thoroughly blended to ensure a homogeneous melt. This

automated process delivers consistent foam structure and reliable extrusion

performance.

Accurate Blowing Gas Metering and

Density Control

Hydrocarbon blowing agents are precisely metered using ATEX-compliant,

high-pressure diaphragm pumps with mass flow measurement, ensuring stable foam

density, uniform cell structure, and high-quality finished products.

Advanced Single-Screw Extrusion

Technology

The system utilizes a long single-screw extruder designed for efficient

plasticizing, mixing, and cooling. Finished foam products are formed through customizable

die heads with single- to four-port configurations, allowing flexible output

capacity and profile design.

An integrated cooling and shaping section ensures dimensional stability and consistent product performance. Finished products are smoothly conveyed by a caterpillar-type haul-off unit and accurately cut by a guillotine cutter, followed by automatic stacking or packaging for efficient downstream handling.

Applications

Cushion & Protection

Specifications

| MODEL | FEX65 | FEX75 | FEX90 |

|---|---|---|---|

|

Material

|

LDPE

|

LDPE

|

LDPE

|

|

Sleeve internal dia.

|

12~75mm

|

12~100mm

|

12~120mm

|

|

Sleeve wall thickness

|

6; 10; 15; 20; 25; 30mm

|

6; 10; 15; 20; 25; 30mm

|

6; 10; 15; 20; 25; 30mm

|

|

Rod Dia.

|

/

|

Up to 75mm

|

Up to 90mm

|

|

Sheet Thickness

|

EPE: 0.8~ 6mm

|

EPE: 0.8~ 6mm

|

EPE: 0.8~ 6mm

|

|

Net mesh

|

Single or double

|

Single or double

|

/

|

|

Net Throughput

|

10~30 kg/hr

|

15~40 kg/hr

|

/

|

|

Sheet Width

|

1,000mm

|

1000~1,500mm

|

1000~1,500mm

|

|

Sheet Throughput

|

40 kg/hr

|

60 kg/hr

|

100 kg/hr

|

|

Density

|

22~30 kg/M3

|

22~30 kg/M3

|

22~30 kg/M3

|

|

Extruder Type

|

Long Single

|

Long Single

|

Long Single

|

|

Screw dia.

|

65mm

|

75mm

|

90mm

|

|

L/D

|

52/1

|

52/1

|

52/1

|

|

Blowing agent

|

Duplex or Triple Diaphragm Pump - Hydrocarbon

|

Duplex or Triple Diaphragm Pump - Hydrocarbon

|

Duplex or Triple Diaphragm Pump - Hydrocarbon

|

|

Drive System

|

SIEMENS AC drive with FLENDER gearbox or equivalent

|

SIEMENS AC drive with FLENDER gearbox or equivalent

|

SIEMENS AC drive with FLENDER gearbox or equivalent

|

|

Cooling system

|

Air cool combined with

Proportional motorized water cool |

Air cool combined with

Proportional motorized water cool |

Air cool combined with

Proportional motorized water cool |

|

Space requirement

|

10(L) x 3(W) x 4(H) m

|

12(L) x 3(W) x 4(H) m

|

15(L) x 3(W) x 4(H) m

|