IRD Crystallizing & Drying Handling System

High-Speed Infrared Drying & Crystallizing Solution for PET and Hygroscopic Plastics

- Application: 30% virgin + 30% regrind APET from in-house + 40% regrind APET from post consumed

- Buck density: virgin 0.75 g/cm3 + regrind 0.4 g/cm3

- Initial material moisture: virgin 0.4%; regrind 0.6%

- Handling capacity: 200~2,200 kgs/hr

- Process time: 12 min. (approximate)

Features

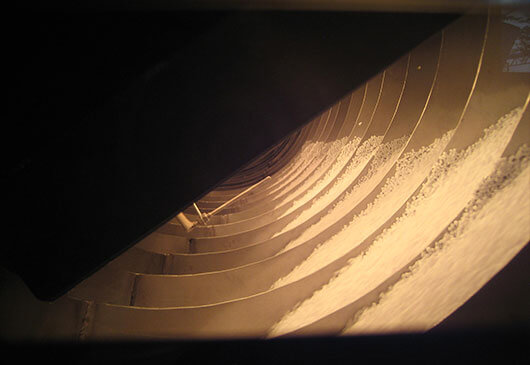

By combining high-efficiency infrared radiation with a continuous rotating drum design, the Sunwell IRD system delivers extremely fast and uniform moisture removal. Direct energy transfer to the pellets significantly shortens drying time while ensuring stable material quality and consistent downstream processing.

High-Speed Infrared Drying Technology

Direct infrared radiation penetrates pellets efficiently, providing rapid and

uniform heating. Compared with conventional hot-air or dehumidifying dryers,

the IRD system achieves significantly faster drying performance.

Rapid Moisture Reduction for PET

Processing

The system can reduce moisture content from over 4,000 ppm to below 50 ppm

within minutes, preventing hydrolysis and maintaining stable IV values during

PET extrusion and molding.

Integrated Crystallizing and Drying

Process

A rotating tumbling drum ensures continuous material mixing and even exposure

to infrared energy, allowing crystallizing and drying to be completed in one

single, continuous operation.

Energy-Efficient and Stable Operation

Infrared technology heats the material directly rather than the surrounding air,

resulting in lower energy consumption, faster start-up, and improved process

stability.

Compact Design with Easy Line

Integration

The IRD system features a small footprint and can be easily integrated into:

-

PET sheet and film extrusion lines

-

Injection molding processes

-

Blow molding applications

-

rPET recycling and reprocessing lines

PLC-Based Temperature and Process

Control

A PLC-controlled system with real-time monitoring ensures precise temperature

control, consistent drying conditions, stable material properties, and improved

final product quality.

The IRD system effectively removes both surface and internal moisture from recycled PET, enabling higher rPET content, improved melt stability, and more consistent production results.

Applications

Specifications

| MODEL | IRD150-270 | IRD180-270 | IRD180-360 | IRD180-450 |

|---|---|---|---|---|

|

Drum size (Dia. x L mm) |

1500 x 2700 | 1800 x 2700 | 1800 x 3600 | 1800 x 4500 |

|

Feeder size (Dia. x L mm) |

139 x 650 | 139 x 650 | 139 x 650 | 139 x 650 |

|

Output capacity (kgs/h) |

~500 | ~800 | ~1200 | ~1500 |

| Temp. control zones | 3 | 3 | 4 | 5 |

| Heater banks | 3 | 3 | 4 | 5 |

| Infrared lamps power (kW) | 135 | 135 | 180 | 225 |

|

Feeding power (kW) |

0.75 | 0.75 | 0.75 | 0.75 |

|

Drum turning power (kw) |

0.75 x 2 | 0.75 x 2 | 0.75 x 2 | 0.75 x 2 |

|

Cooling Blower (kw) |

2.2 | 3.7 | 3.7 | 5.5 |

|

Extraction fan (kW) |

2.2 | 3.7 | 3.7 | 5.5 |