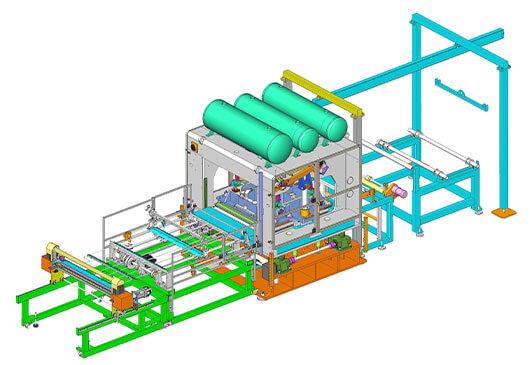

Contact Heating Thermoforming Machine

Energy-Efficient Pressure & Vacuum

Thermoforming for Thin-Gauge Packaging

- Forming Method: Vacuum Forming / Pressure Forming

- Maximum Sheet Width: 1100 mm (details see specification)

- Maximum Dry Cycle Speed: 35 cycle/min

Features

Sunwell Global’s Contact Heating

Thermoforming Machine is specifically designed for the production of

thin-gauge, shallow-draw BOPS packaging products. By utilizing direct contact

heating technology instead of a conventional heating oven, this system delivers

excellent forming accuracy, reduced energy consumption, and enhanced production

safety.

Direct Contact Heating Technology

The SF1100 model heats the plastic sheet directly through a contact heating platen, eliminating the need for a traditional heating oven. This design significantly reduces energy consumption and floor space, while preventing sheet sagging during heating and minimizing fire risks.

Wide Material Compatibility

Capable of processing BOPS, HIPS, and PET, the machine produces a wide

range of thin-gauge food containers with consistent forming quality and

excellent surface finish.

Servo-Driven Precision Forming System

The top moving platen is servo motor driven and connected to a mechanical

toggle system, providing precise motion control, accurate positioning, and

stable forming pressure for repeatable, high-quality results.

Multi-Layer Heating and Forming Platen

Design

The fixed bottom platen features a four-layer structure:

- Surface plate with thousands of micro air holes for uniform pressure forming

- Airflow channel plate for controlled forming air distribution

- Integrated aluminum cast-in heaters with multi-zone temperature control

- Thermal insulation plate to improve energy efficiency

This structure ensures uniform heating, precise air control, and stable forming performance.

Enhanced Safety and Process Control

Multiple heating and forming zones are matched to different mold sizes. The

forming area is fully protected by safety guards and light curtains, while

individual air on/off control valves allow fine-tuned forming precision.

Flexible Sheet Transfer and Cutting

Options

The formed sheet is indexed by a reciprocating timing belt system for accurate length

control. The system can be configured with:

- A cross flying cutter and stacker for off-line secondary cutting

- Edge marking punchers for easy quantity identification

- In-line vertical trim press for high-speed, mass production

Applications

Food Containers

Plates / Dishes

Specifications

| MODEL | SF-1100 |

|---|---|

|

Configuration

|

Contact Heating Platen

|

|

Application

|

Shallow Containers for Thin Gauge Sheet of BOPS; HIPS; PET etc.

|

|

Forming Method

|

Vacuum/ Pressure Forming

|

|

Forming Direction

|

Upper Sheet Forming

|

|

Maximum Sheet Width

|

1,100 mm

|

|

Maximum Forming Area

|

1,050 x 1,050 mm

|

|

Minimum Forming Area

|

700 x 700 mm

|

|

Max. Depth of Draw

|

50 mm

|

|

Clamping Tonnage

|

75 tons

|

|

Shut-height

|

55-150 mm

|

|

Platen Travel

|

150 mm

|

|

Max. Dry Cycle Speed

|

35 cycle/min

|

|

Top Platen Drive

|

AC Servo Driven Toggle Linkage

|

|

Sheet Index

|

AC Servo Driven with Grip Pull System

|

|

Products Cutting

|

Inline Vertical Trim Press or Off-Line with Hydraulic Cutting Machine

|

|

Control System

|

YASKAWA PLC with Touch Screen

|

|

Floor Space

|

8L x 2.5W x 3.5H M

|