MS系列成型在線裁切系統

成型裁斷機提供高速及量產淺底類的產品運用

- 成型方式:壓空成型

- 最大皮料寬:900-1460mm (詳細請參閱規格)

- 最大空跑速度:40 cycle/min (詳細請參閱規格)

特色

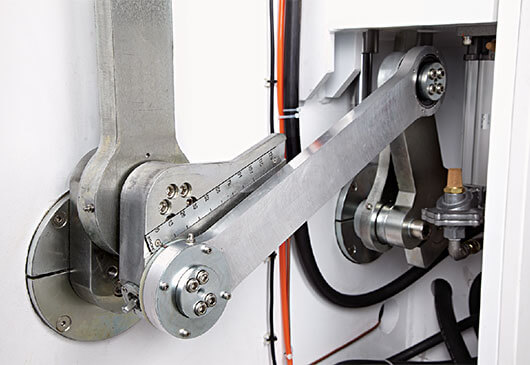

昇威MS系列連續性各獨立式工作站提供生產高技術與高效率發泡類產品。精確的控制和處理能力讓客戶生產押出皮料運用更廣,包括PS、PP和PE。系統包括兩獨立工作站,分別為成型站,接連著為裁斷站,下方同時有連線的粉粹機,自動粉碎裁切後廢料。成型站為2軸伺服驅動,連接機械肘節,肘節可獨立開閤上下成型基板。熱爐配置高品質的陶瓷加熱片,分佈多個溫控區,更能精準確認皮料各部位溫度。皮料由鏈條推動前進,由伺服馬達控制,步進行程與同步訊號以及控制程式介面。臥式(或可選立式)裁斷機透過伺服電機控制來運作,並有增加行程的延伸長度,便高深底容器進行沖孔以裁切。另外兩個伺服動作控制產品行程與推杯功能,將成品精準裁切運至包裝台上進行包裝。裁斷後的下腳料直接與裁斷機下裁切,而後輸送至回收製粒,節省空間與人力需求。

應用範圍

塑膠盤/碟

快餐盒

生鮮雞肉/肉類拖盤

規格

| MODEL | MS900 | MS1200 | MS1370 | MS1460 |

|---|---|---|---|---|

|

Configuration

|

Forming front, post trim with scrap granulation inline

|

Forming front, post trim with scrap granulation inline

|

Forming front, post trim with scrap granulation inline

|

Forming front, post trim with scrap granulation inline

|

|

Application

|

Foam products or thin gauge shallow products

|

Foam products or thin gauge shallow products

|

Foam products or thin gauge shallow products

|

Foam products or thin gauge shallow products

|

|

Forming method

|

Vacuum and slight pressure forming

|

Vacuum and slight pressure forming

|

Vacuum and slight pressure forming

|

Vacuum and slight pressure forming

|

|

Forming direction

|

Either above or below sheet forming

|

Either Above or Below Sheet Forming

|

Either Above or Below Sheet Forming

|

Either above or below sheet forming

|

|

Maximum Sheet Width

|

900 mm

|

1,200 mm

|

1,370 mm

|

1,460mm

|

|

Mold Size

(mm) |

Max. 850 x 1,000

Min. 600 x 760 |

Max. 1,150 x 1,200

Min. 850 x 800 |

Max. 1,320 x 1,350

Min. 1,000 x 1,000 |

Max. 1,400 x 1,500

Min. 1,000 x 1,000 |

|

Max. Depth of Draw

|

100 mm

|

100 mm

|

100 mm

|

100 mm

|

|

Forming Tonnage (ton)

|

80 tons

|

80 tons

|

80 tons

|

80 tons

|

|

Shut-height (mm)

|

Top = 150

Bottom = 150 |

Top = 150

Bottom = 150 |

Top = 150

Bottom = 150 |

Top = 150

Bottom = 150 |

|

Platen Travel

|

Top = 180

Bottom = 180 |

Top = 180

Bottom = 180 |

Top = 180

Bottom = 180 |

Top = 180

Bottom = 180 |

|

Max. Dry Cycle Speed

|

50 cycles / Min.

|

50 cycles / Min.

|

50 cycles / Min.

|

50 cycles / Min.

|

|

Platen Drive

|

AC Servo driven;

Toggle linkage |

AC Servo driven;

Toggle linkage |

AC Servo driven;

Toggle linkage |

AC Servo driven;

Toggle linkage |

|

Sheet Index

|

AC Servo Driven Chain Feed

|

AC Servo Driven Chain Feed

|

AC Servo Driven Chain Feed

|

AC Servo Driven Chain Feed

|

|

Heat Tunnel Length

|

4,000 mm

|

5,000 mm

|

5,600 mm

|

6,000 mm

|

|

Heating Elements

|

Ceramic

|

Ceramic

|

Ceramic

|

Ceramic

|

|

In line with Trim Press

|

Horizontal Trim Press or Alternative

|

Horizontal Trim Press or Alternative

|

Horizontal Trim Press or Alternative

|

Horizontal Trim Press or Alternative

|

|

Trim Press Drive

|

AC Servo driven; Crank reciprocatedrun

|

AC Servo driven; Crank reciprocatedrun

|

AC Servo driven; Crank reciprocatedrun

|

AC Servo driven; Crank reciprocatedrun

|

|

Trimming Max. Speed

|

160 cpm

|

160 cpm

|

160 cpm

|

160 cpm

|

|

Trimming Tonnage

|

20 tons

|

20 tons

|

20 tons

|

20 tons

|

|

Control System

|

YASKAWA 2200

|

YASKAWA 2200

|

YASKAWA 2200

|

YASKAWA 2200

|

|

Floor Space (M)

|

20L x 4W x 4H M

|

22L x 4W x 4H M

|

23L x 4.5W x 4H M

|

24L x 5W x 4H M

|

|

Machine Weight

|

12,000 kg

|

14,000 kg

|

16,000 kg

|

18,000 kg

|