MC系列全自動一體多段式熱成型機

一體多段式熱成型機

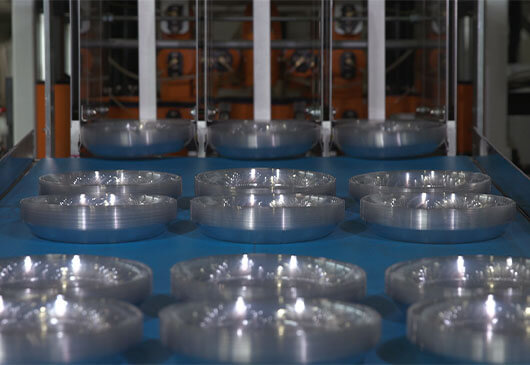

成型裁斷堆疊多段式機台提供薄壁型食品包裝及工業用盛裝容器應用

- 成型方式:真空成型/壓空成型

- 最大皮料寬:320-820mm (詳細請參閱規格)

- 最大空跑速度:60 cycle/min (詳細請參閱規格)

特色

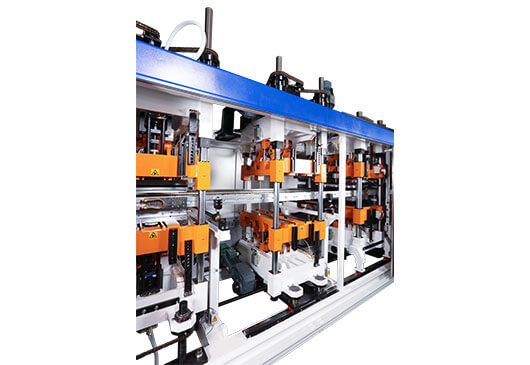

昇威MC系列是一款全自動一體式多工位熱成型機。集結了伺服送料、片材加熱、正負壓吸塑成型、產品沖孔、產品沖裁、計數疊料、自動取出、下腳料收取一體化功能。昇威MC系列熱成型機精緻的設計方式,有節能精密的溫控,絶對值全伺服系統的肘節傳動,生產高品質產品穩定性與可靠性均高的設備,生產速度最高可達到每分鐘60cpm,對加工PP、PS、OPS、EPS、 PE、PVC、APET還是CPET、PLA都非常適用。精緻小巧刀模及快速換模機構提供模具快速更換,減少產線時間,特別適合各式中小批量的生產,具高效益與低成本優勢。非常適用於食物、食品、化妝品、醫療用品、玩具、電器電子元件、日用五金商品等的各式薄殼包裝。

應用範圍

杯蓋

食品盛裝盒

水果盒

塑膠盤/碟

快餐盒

生鮮雞肉/肉類拖盤

規格

| MODEL | MCS800 | MCS1000 |

|---|---|---|

|

Configuration

|

Form-Cut-Stack Multi-Station; steel rule die technology

|

Form-Cut-Stack Multi-Station; steel rule die technology

|

|

Application

|

Thin wall food and industrial packaging

|

Thin wall food and industrial packaging

|

|

Stations No.

|

3 or 4

|

3 or 4

|

|

Max. Cycle Speed

|

60 cycles / Min.

|

50 cycles / Min.

|

|

Sheet Index

|

AC Servo driven chain index feed

|

AC Servo driven chain index feed

|

|

Heat Tunnel Length (mm)

|

1,800

|

2,400

|

|

Heating Elements

|

Ceramic

|

Ceramic

|

|

Forming method

|

Positive and negative pressure forming

|

Positive and negative pressure forming

|

|

Forming direction

|

Either above or below sheet forming

|

Either above or below sheet forming

|

|

Maximum Sheet With (mm)

|

860

|

1060

|

|

Forming Mold Size (mm)

|

Max. 570(L) x 820(W)

Min. 250 (L) x 290(W) |

Max. 750(L) x 1000(W)

Min. 450 (L) x 500(W) |

|

Max. Depth of Draw (mm)

|

130

|

130

|

|

Shut-height (mm)

|

Top: 250~350

Bottom: 200~250 |

Top: 250~350

Bottom: 200~250 |

|

Platen Travel (mm)

|

Top: 150

Bottom: 150 |

Top: 150

Bottom: 150 |

|

Forming Platen Driven

|

AC Servo; toggle mechanism actuation

|

AC Servo; toggle mechanism actuation

|

|

Forming Tonnage (tons)

|

30

|

50

|

|

Pre-Punch Mold Size (mm)

|

Max. 570(L) x 820(W)

Min. 250(L) x 290(W) |

Max. 750(L) x1000(W)

Min. 400(L) x 290(W) |

|

Shut-height (mm)

|

Top: 250~350

Bottom: 250 |

Top: 250~350

Bottom: 250 |

|

Platen Travel (mm)

|

Top: 150

Bottom: 150 |

Top: 150

Bottom: 150 |

|

Pre-punch Driven

|

AC Servo; toggle mechanism actuation

|

AC Servo; toggle mechanism actuation

|

|

Pre-punch Tonnage (tons)

|

30

|

30

|

|

Cutting Size (mm)

|

550(L) x 800(W)

|

730(L) x 980(W)

|

|

Shut-height (mm)

|

Top: 85~185

Bottom: 180 |

Top: 85~185

Bottom: 180 |

|

Platen Travel (mm)

|

Top = 150

|

Top = 150

|

|

Cutting Tonnage (tons)

|

60

|

90

|

|

Stacking Size (mm)

|

550(L) x 800(W)

|

730(L) x 980(W)

|

|

Stacking Method

|

Up or Down stacking by servo; Robotic is option

|

Up or Down stacking by servo; Robotic is option

|

|

Control System

|

B&R or YASKAWA

|

B&R or YASKAWA

|

|

Floor Space (M)

|

12.5(L) x 3.3(W) x 3.3(H)

|

14(L) x 3.6(W) x 3.3(H)

|

|

Machine Weight (kg)

|

12,000

|

16,000

|